Palletising Solutions (Automatic & Robotic)

Palletising Solutions (Automatic & Robotic)

Palletising Solutions: Automatic & Robotic

Palletising Solutions: Automatic & Robotic

At Modern Industrial Automation Solutions Pvt. Ltd., we specialize in delivering high-performance automatic and robotic palletizing systems tailored to meet the evolving needs of modern manufacturing and logistics. Our solutions are designed to enhance efficiency, accuracy, and flexibility at your end-of-line operations—whether you are stacking cartons, crates, bags, drums, or mixed product types.

With a focus on seamless integration, modular scalability, and robust construction, our palletizing technologies ensure a smooth transition from production lines to dispatch-ready pallets. Backed by expert engineering, advanced automation, and customizable configurations, we help you minimize labor dependency, reduce downtime, and accelerate throughput across diverse industrial environments.

Automatic (Conventional) Palletizers

Conventional palletizers are rugged, high-speed mechanical systems engineered for efficiently stacking uniform products such as cartons, bags, or cases. These machines are ideal for high-throughput operations where consistent stacking patterns and predictable product shapes are the norm.

Automatic (Conventional) Palletizers

Conventional palletizers are rugged, high-speed mechanical systems engineered for efficiently stacking uniform products such as cartons, bags, or cases. These machines are ideal for high-throughput operations where consistent stacking patterns and predictable product shapes are the norm.

Key Features

Floor-Level (Low-Level) Palletizers

Products are introduced at floor level and elevated for stacking. The pallet remains stationary or lowers gradually as each layer is completed.

✅ Suitable for moderate speeds: 20–40 cases per minute

✅ Ideal for FMCG, food, and packaging lines

High-Level Palletizers

Products enter from an elevated infeed and are organized into layers at height. A sweep bar or plate pushes each complete layer onto the pallet.

✅ Designed for high-speed applications: Up to 100 cases per minute

✅ Common in beverage, consumer goods, and industrial sectors

Gantry or Layer Palletizers

Uses a gantry-style system or Cartesian robots to place products with extreme accuracy. Either the product or the pallet moves in X-Y coordinates.

✅ Ideal for heavy or delicate items like drums, buckets, or pails

✅ Custom-built for unique stacking needs

Robotic Palletizing Systems

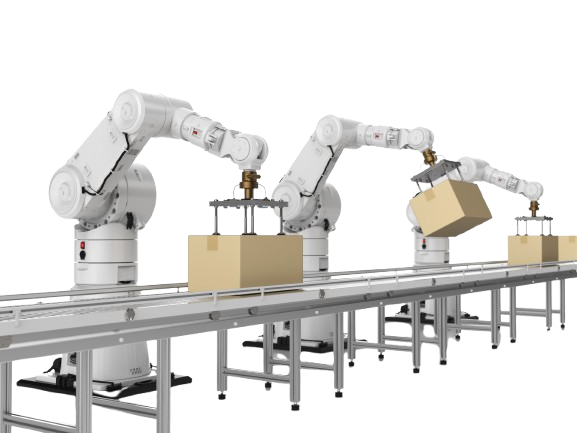

Our robotic palletizers feature advanced 4-axis or 6-axis robotic arms with specialized end-effectors that pick and place products with precision and flexibility. These systems are perfect for dynamic, space-constrained, or multi-product environments.

Robotic Palletizing Systems

Our robotic palletizers feature advanced 4-axis or 6-axis robotic arms with specialized end-effectors that pick and place products with precision and flexibility. These systems are perfect for dynamic, space-constrained, or multi-product environments.

Key Features

Single Pallet Station Robots

Robotic arms placed at the end of a production line to stack products onto a single pallet station with programmable precision.

✅ Ideal for compact lines with repetitive stacking needs

Multi-Line / Multi-Pallet Robots

One robot serves multiple conveyors or pallet stations. Efficient for handling 2–4 SKUs simultaneously, even from separate production lines.

✅ Optimizes space, labor, and capital investment

Collaborative Robots (Cobots)

Safe, compact, and easy to deploy, cobots can work alongside human operators without the need for safety cages.

✅ Perfect for lower-speed applications or frequent product changeovers

✅ User-friendly programming for fast adaptation

Hybrid & Integrated Palletizing Solutions

Hybrid palletizing solutions combine the strengths of conventional machinery and robotic automation to deliver unmatched flexibility, speed, and space efficiency. These systems are ideal when you need to balance product variety, throughput, and space optimization.

Hybrid & Integrated Palletizing Solutions

Hybrid palletizing solutions combine the strengths of conventional machinery and robotic automation to deliver unmatched flexibility, speed, and space efficiency. These systems are ideal when you need to balance product variety, throughput, and space optimization.

Key Features

Robotic Arms + Conventional Row Forming

In this setup, robotic arms are used for product picking, while the final layer formation and palletizing are handled by a conventional palletizer.

✅ Faster row forming with robotic flexibility

✅ Great for lines with variable SKUs but high throughput targets

Integrated AGV/AMR Systems

We integrate Autonomous Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) to automate the movement of pallets—delivering empty pallets to stations and taking away filled ones.

✅ Reduces manual intervention

✅ Ideal for smart factory and Industry 4.0 environments

Multi-Technology Synchronization

We design custom layouts that combine robotics, mechanical palletizers, smart conveyors, and automated storage to suit your production environment.

✅ Works across multiple packaging lines

✅ Can handle mixed product types with ease

✅ Built for scalability and future upgrades

Palletising Solutions Features & Benefits

Palletising Solutions Features & Benefits

| Feature | Description | Benefit |

|---|---|---|

| Throughput & Productivity | Automated palletizers operate continuously, significantly faster than manual stacking. | Eliminates end-of-line bottlenecks, directly boosting production speed and volume. |

| Labor Savings & Safety | Removes workers from strenuous, repetitive, and risky lifting duties. | Eliminates fatigue, strained backs, and accident risks, reassigning staff to higher-value roles. |

| Consistency & Stack Quality | Automated systems stack products with unparalleled precision, layer by layer. | Creates uniform, tightly packed loads, reducing product crushing and improving load stability for transport. |

| Flexibility (Robotic Systems) | Robotic palletizers can be rapidly reprogrammed for new products, patterns, or multiple SKUs. | Easily adjusts to product changeovers and evolving demands, offering versatile multi-SKU handling. |

| Improved OEE & Stability | Contributes to Overall Equipment Effectiveness by reducing variability and downtime. | Sustains consistent pace 24/7, unaffected by worker fatigue or absenteeism, increasing OEE. |

| Cost Savings & ROI | Leads to reduced labor costs, fewer workplace injury claims, and higher output. | Systems often pay for themselves quickly through significant operational savings and increased capacity. |

| Seamless Integration | Our solutions are designed to integrate with ASRS, AGVs/AMRs, and conveyors. | Creates a continuous, efficient intralogistics flow, minimizing manual touches and forklift transfers. |

Process Today

Ready to eliminate the bottlenecks, mitigate the risks, and boost the efficiency of your end-of-line operations? Our cutting-edge palletising solutions – encompassing both robust conventional systems and highly flexible robotic solutions – are expertly tailored to streamline your packaging process.

Modern Industrial Automation Solutions Pvt. Ltd. will meticulously assess your unique needs and propose the ideal system to maximize throughput, drastically improve safety, and ensure impeccable stack integrity for all your products.

Contact us today for a personalized consultation and discover how we can transform your palletizing operations!