Telescopic Conveyors

Telescopic Conveyors

Telescopic Conveyors

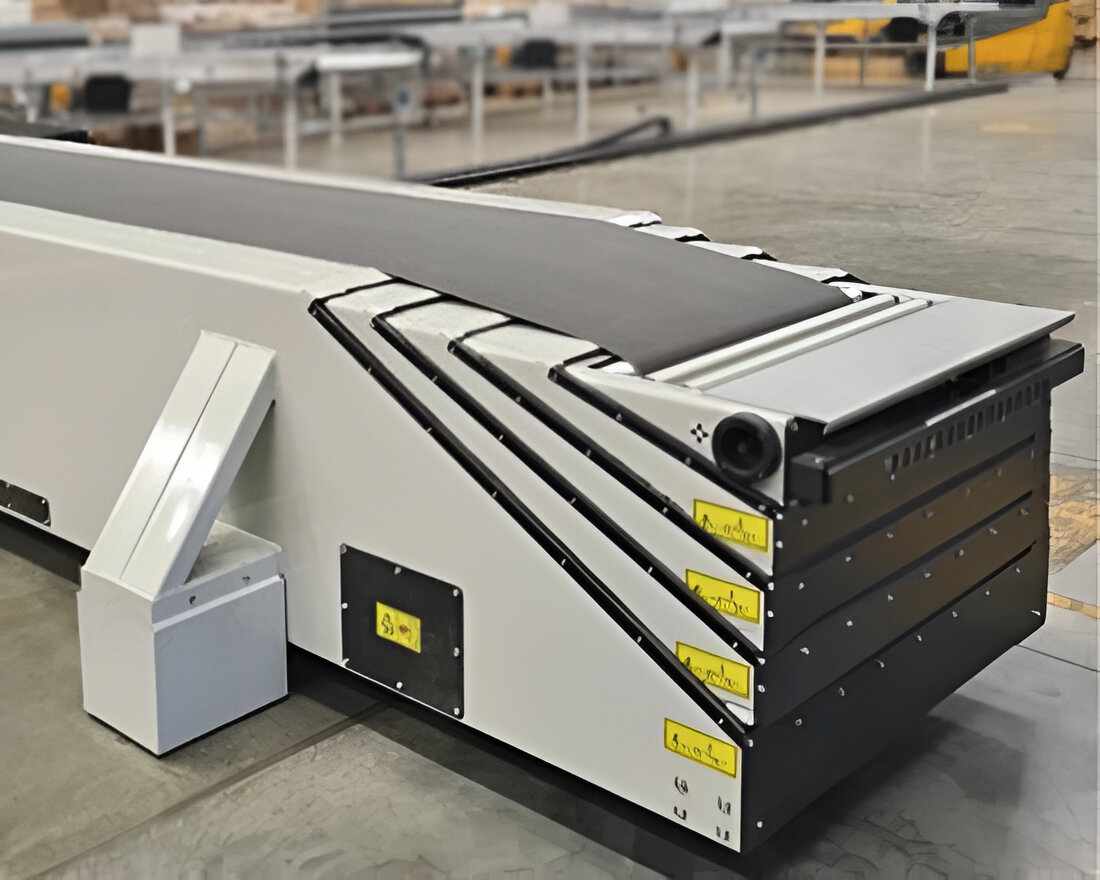

Modern Industrial Automation Solutions Pvt. Ltd. offers Telescopic Conveyors as a vital component of automated loading systems. These extendable belt conveyor systems streamline truck and container loading/unloading, reducing labor and improving turnaround times in distribution centers.

What Are Telescopic Conveyors

Telescopic conveyors are extendable conveyors that reach directly into trucks, trailers, and containers, bridging the gap between warehouse floors and vehicle bays. By eliminating manual package carrying, they enhance efficiency, reduce labor fatigue, and ensure smoother logistics operations.

Telescopic Conveyors

Modern Industrial Automation Solutions Pvt. Ltd. offers Telescopic Conveyors as a vital component of automated loading systems. These extendable belt conveyor systems streamline truck and container loading/unloading, reducing labor and improving turnaround times in distribution centers.

What Are Telescopic Conveyors

Telescopic conveyors are extendable conveyors that reach directly into trucks, trailers, and containers, bridging the gap between warehouse floors and vehicle bays. By eliminating manual package carrying, they enhance efficiency, reduce labor fatigue, and ensure smoother logistics operations.

Use Cases & Applications

Use Cases & Applications

Telescopic conveyors are ideal for industries requiring high-throughput, efficient logistics:

Parcel & Courier Logistics

Used in postal centers and 3PLs for fast loading/unloading of packages, especially in high-volume courier hubs.

E-Commerce Fulfillment

Accelerates outbound logistics during peak seasons, ensuring on-time delivery and reducing labor fatigue.

Retail & FMCG Distribution

Loads cartons of consumer goods such as packaged food, beverages, and electronics with minimal manual effort.

Manufacturing & Warehousing

Facilitates bulk shipment of goods like appliances, automotive parts, or loose cartons.

Ports & Airports

Used for container stuffing at ports and air cargo handling at airports—ideal for tight turnaround timelines.

Telescopic Conveyor Features & Benefits

Telescopic Conveyor Features & Benefits

| Feature | Description | Benefit |

|---|---|---|

| Extendable Boom | Reaches deep into trucks | Reduces loading time and walking effort |

| Reversible Belt Direction | Load and unload with the same conveyor | Improves versatility and efficiency |

| Adjustable Height | Aligns with truck beds or mezzanine floors | Ergonomic and safe for workers |

| Integrated Accessories | Optional barcode scanners, weighing, SKU counters | Automates parcel data capture and tracking |

| Built-in Safety | Emergency stops, bumpers, alarms, and guarding | Enhances worker safety and operation control |

| Robust Build | Industrial-grade materials and low-maintenance components | Long-lasting and reliable under heavy use |

| Space Efficient | Retracts when not in use | Saves dock space and allows easy maneuvering |

Case Study: E-Commerce Fulfillment Center Success

Case Study: E-Commerce Fulfillment Center Success

Challenge

Solution

Outcome

Process Today

Ready to eliminate the bottlenecks, mitigate the risks, and boost the efficiency of your end-of-line operations? Our cutting-edge palletising solutions – encompassing both robust conventional systems and highly flexible robotic solutions – are expertly tailored to streamline your packaging process.

Modern Industrial Automation Solutions Pvt. Ltd. will meticulously assess your unique needs and propose the ideal system to maximize throughput, drastically improve safety, and ensure impeccable stack integrity for all your products.

Contact us today for a personalized consultation and discover how we can transform your palletizing operations!