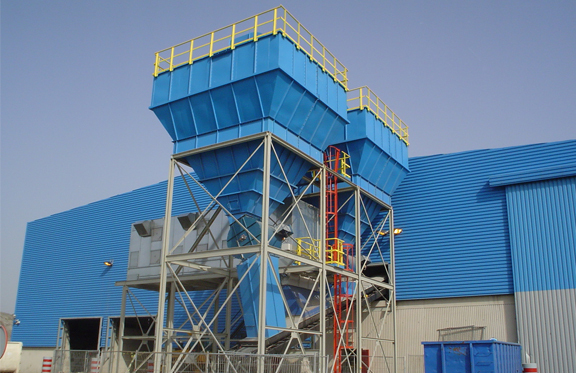

Storage Hoppers

Storage Hoppers

Storage Hoppers

At Modern Industrial Automation Solutions Pvt. Ltd., we design and deliver high-performance Storage Hoppers engineered to streamline bulk material handling with precision, safety, and efficiency. These intermediate containers are essential in a wide range of industries, serving as temporary storage units for materials such as grains, powders, pellets, granules, aggregates, and other bulk solids before they enter the next stage of production or packaging.

Equipped with smart flow-assist features like vibratory aids, cone angles optimized for flow, aeration pads, or screw feeders, our hoppers ensure consistent and uninterrupted material discharge. This reduces bridging, rat-holing, and clogging—common issues in bulk material handling—resulting in smoother operations and minimal downtime.

Hopper Types & Design Options

Fixed hoppers supported on legs or frames for bulk storage. Top-filled and bottom-discharged into conveyors, screw feeders, or mixers. Customizable angles (>40°), capacities (from 5 to 50 tons), and materials (MS, SS) to suit application needs

Discharge Aids & Flow Enhancements

Applications Across Industries

Food & Agri

Used in mills, breweries, and feed plants to hold grains, flour, sugar, malt, and soybean meal. Ensures constant supply to mixers or packaging lines.

Packaging & Bagging

Hoppers above bagging machines feed materials like rice or fertilizer with minimal spillage and downtime.

Chemicals & Plastics

Used for resins, pellets, powders in extrusion or molding processes. May include inert gas systems for flow-sensitive materials.

Waste & Recycling

Collects sawdust, scrap, or glass before processing. Self-dumping models for easy handling.

Construction

Feed hoppers for sand, aggregates, or asphalt at mixing or paving sites.

Pharma

Sanitary-grade stainless steel hoppers used for powders or pills in production lines, ensuring contamination-free handling.

Key Benefits

| Type | Description |

|---|---|

| Continuous Operations | Hoppers act as buffers between batch processes, ensuring steady downstream flow even if upstream supply pauses |

| Labor Efficiency | Reduces manual scooping or refilling. A single hopper load can sustain hours of production, freeing staff for other tasks. |

| Accurate Material Control | With valves and feeders, hoppers allow consistent metering—ideal for batching, blending, or packaging. |

| Compact Footprint | Tall hoppers save space by utilizing vertical storage instead of spreading materials horizontally. |

| Cleaner & Safer | Minimizes dust, spillage, and contamination. Optional dust covers, sealing, and extraction ports enhance hygiene and safety. |

| Material Protection | Keeps sensitive materials enclosed and stable. Prevents segregation or spoilage, especially in food and chemical applications. |

| Automation-Ready | Compatible with conveyors, level sensors, and PLCs. Enables autonomous refill triggers and remote monitoring. |

Process Today

Ready to eliminate the bottlenecks, mitigate the risks, and boost the efficiency of your end-of-line operations? Our cutting-edge palletising solutions – encompassing both robust conventional systems and highly flexible robotic solutions – are expertly tailored to streamline your packaging process.

Modern Industrial Automation Solutions Pvt. Ltd. will meticulously assess your unique needs and propose the ideal system to maximize throughput, drastically improve safety, and ensure impeccable stack integrity for all your products.

Contact us today for a personalized consultation and discover how we can transform your palletizing operations!