Automated Guided Vehicles

Automated Guided Vehicles

Automated Guided Vehicles

Modern Industrial Automation Solutions Pvt. Ltd. offers Automated Guided Vehicles (AGVs) as a core part of our warehouse automation portfolio. These driverless vehicles carry materials through predefined paths in your facility, serving as robotic “workers” that can operate 24/7 without direct human intervention.

AGVs are a well-proven technology for the internal transportation of goods, pallets, and parts. They navigate using various guidance systems (such as magnetic tapes, wires in the floor, laser targets, or QR codes) and are controlled by a central system to ensure timely and safe movement of materials. In an era where efficiency and labor optimization are key, AGVs provide a reliable way to automate repetitive transportation tasks like moving raw materials to production lines, transferring finished goods to warehouses, or delivering components to assembly stations.

Types Of Automated Guided Vehicles

Types Of Automated Guided Vehicles

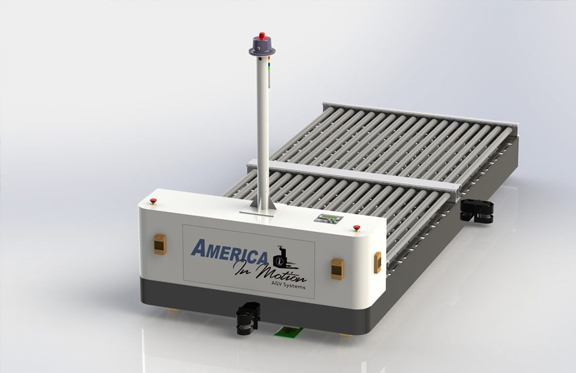

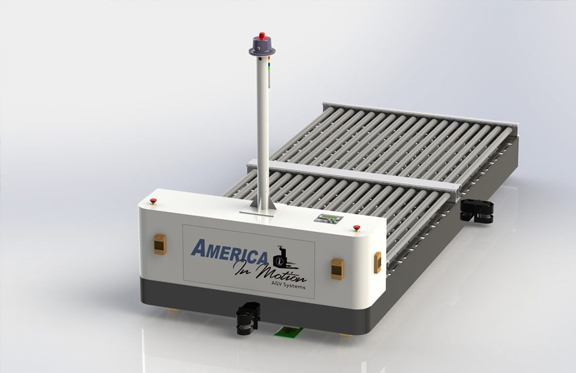

Unit Load AGVs

These AGVs carry individual loads on their platform, often with a flat deck or a conveyor top. They are ideal for moving pallets, boxes, or totes. For example, a unit-load AGV might move pallets of finished goods from a packaging line to an ASRS entry point.

- Specifications: Typically carry up to 1-2 tons, move at speeds around 1–2 m/s (slow when loaded for safety), and can have lift mechanisms if needed (some have scissor lifts for pickup/drop-off).

- Navigation: Can be laser-guided (reflectors on walls) or magnetic/QR guide paths.

Forklift AGVs (Automated Forklifts)

These are essentially robotic forklifts capable of lifting and stacking pallets. They can pick up pallets from the floor or racks and transport them. They have sensors to align with pallets and forks that lift like a standard forklift (heights vary; some can reach the second level of racking). This type is popular in warehouses to replace manual fork trucks for tasks like pallet moves and truck loading.

- Capacity: Ranges widely – 1 to 3 tons typical.

- Navigation: Often use laser navigation for flexibility.

Tugger AGVs (Towing Vehicles)

These AGVs pull one or more non-powered carts (like a train). Often used in manufacturing for line-side delivery – e.g., an AGV tug pulling carts loaded with parts from the warehouse to assembly stations on a scheduled route (the “milk run” concept).

- Capacity: Can tow significant weight (several tons depending on the number of carts).

- Navigation: Follow fixed routes marked by magnetic tape or wires in many cases.

Light Load AGVs & AMR Hybrids

For lighter loads (components, trays, smaller bins), we also offer compact AGVs which are closer to AMRs (Autonomous Mobile Robots). These might navigate freely (without fixed paths) but serve similar purposes, like delivering parts or picking up mail bins in an office. One common form is an AGV with a robotic arm on top for item picking in warehouses. While these blur the line with AMRs, we categorize guided vehicles that follow specific paths or use infrastructure as AGVs.

Assembly Line AGVs (Cart AGVs)

In some industries (automotive, electronics), AGVs are used as moving assembly platforms. These are low-profile carts that carry products down an assembly line, moving from station to station at a controlled pace (often following a wire or magnetic strip). They replace traditional conveyor belts and allow for flexible assembly layouts.

Use Cases & Applications

Bag stacker conveyors are used across a wide range of industries

Automotive Manufacturing

Heavily used to deliver parts to assembly lines (e.g., engines, seats, dashboards) just in time. They also often carry the car body itself along assembly operations.

Warehousing & Distribution

AGV forklifts and unit-load AGVs transport pallets from inbound to storage or from storage to outbound docks, without human intervention. They ensure continuous flow and can work in dark or lights-out conditions.

Food & Beverage Production

Common in food/beverage plants to move heavy and repetitive loads, such as full pallets of bottled drinks or stacking pallets in aging rooms or cold stores.

Pharmaceutical & Chemical

Benefit from AGVs for handling potentially hazardous or sensitive materials with minimal human contact, helping maintain cleanroom standards and enhancing safety.

Electronics & Appliance Manufacturing

Used to supply assembly lines with parts and carry products between assembly stations or to testing/packaging areas, reducing reliance on fixed conveyors.

General Manufacturing & 3PL

Virtually any manufacturing that has repetitive material flow can use AGVs. 3PL companies also use AGVs in their warehouses, especially where labor turnover is high or to operate in multiple shifts.

Process Today

Ready to eliminate the bottlenecks, mitigate the risks, and boost the efficiency of your end-of-line operations? Our cutting-edge palletising solutions – encompassing both robust conventional systems and highly flexible robotic solutions – are expertly tailored to streamline your packaging process.

Modern Industrial Automation Solutions Pvt. Ltd. will meticulously assess your unique needs and propose the ideal system to maximize throughput, drastically improve safety, and ensure impeccable stack integrity for all your products.

Contact us today for a personalized consultation and discover how we can transform your palletizing operations!