Automated Storage and Retrieval Systems

Automated Storage and Retrieval Systems

ASRS (Automated Storage and Retrieval Systems)

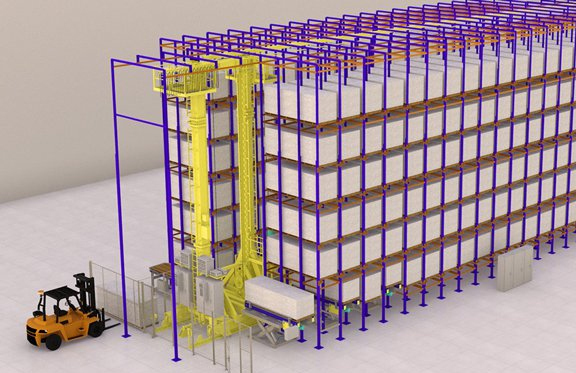

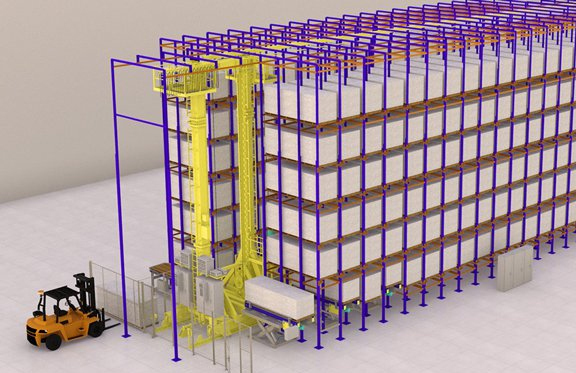

Automated Storage and Retrieval Systems (ASRS) are advanced, computer-controlled systems designed to automatically place, store, and retrieve goods from specific storage locations with high precision. These systems are engineered to optimize space utilization, improve inventory management, and significantly increase operational efficiency in warehouses, distribution centers, and manufacturing facilities.

By integrating automation with intelligent software, ASRS solutions eliminate the need for manual storage and retrieval, thereby reducing labor costs, minimizing human errors, and enhancing safety. They enable high-density storage in vertical or compact footprints, making them especially valuable in space-constrained environments.

TYPES OF ASRS

TYPES OF ASRS

Unit-Load ASRS (For Heavy Pallets)

- Stores large, heavy items like pallets, crates, or drums

- Ideal for factories and large distribution centers

- Tower height: up to 30 meters

- Speed: Handles up to 40 loads/hour

Mini-Load ASRS (For Totes & Bins)

- Handles smaller loads like boxes, tools, components

- Widely used in pharma, e-commerce, electronics

- High-speed operation: 100+ totes/hour

- Integrates with robots, conveyors, and sorters

Shuttle & Robot-Based Systems

- Uses shuttles or cube-based bots to navigate storage racks

- Offers multi-directional movement for rapid picking

- Excellent for dense, high-speed warehousing

- Highly modular and scalable for future growth

Vertical Lift Modules (VLMs) & Carousels

- Compact cabinets that deliver trays to the user

- Saves floor space and improves ergonomics

- Ideal for tools, spare parts, files, electronics

- Easy to operate using touchscreens or WMS software

Specifications at a Glance

| Type | Details |

|---|---|

| Load Capacity | 100 kg to 1500 kg |

| Retrieval Speed | Up to 120 picks/hour |

| Height | Up to 15 meters |

| Accuracy | 99.9% |

| Footprint Reduction | Up to 60% |

| Integration | ERP, WMS, SCADA compatible |

System Types

| Type | Description |

|---|---|

| Vertical Lift Modules (VLMs) | Automated vertical trays – ideal for small parts |

| Shuttle Systems | High-speed, multi-level tote storage |

| Unit Load ASRS | For pallets and heavy items |

| Mini Load ASRS | Small items in bins or cartons |

Key Features & Benefits

Case Study: ASRS in Action

Client

A pharmaceutical distribution center in South India needed to streamline storage and picking operations for thousands of fast- and slow-moving SKUs spread across multiple zones and temperature conditions.

Challenge

The client faced issues with manual storage and retrieval processes, which led to frequent inventory errors, slow picking speeds, and underutilized vertical space within the facility.

Solution

We implemented a customized combination of Mini-Load ASRS and Vertical Lift Modules (VLMs), integrated with smart warehouse software for optimized slotting, fast picking, and real-time stock visibility.

Outcome

The system delivered a threefold increase in throughput, achieved 99.8% order accuracy, reduced storage footprint by 40%, and paid back the investment within just 14 months of deployment.

Process Today

Ready to eliminate the bottlenecks, mitigate the risks, and boost the efficiency of your end-of-line operations? Our cutting-edge palletising solutions – encompassing both robust conventional systems and highly flexible robotic solutions – are expertly tailored to streamline your packaging process.

Modern Industrial Automation Solutions Pvt. Ltd. will meticulously assess your unique needs and propose the ideal system to maximize throughput, drastically improve safety, and ensure impeccable stack integrity for all your products.

Contact us today for a personalized consultation and discover how we can transform your palletizing operations!